Fitting Instructions

The fitting details are dependent on the type of headstock and the type of string rollers. Slotted headstocks can have the two types of classical rollers, plain or with bearing bushes, and brass rollers for steel string. Solid headstocks have top bushes which support the end of the rollers.

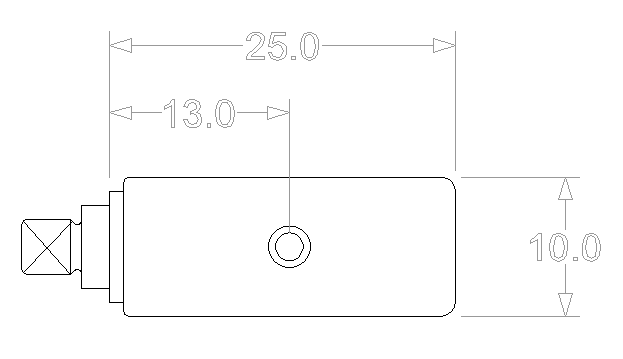

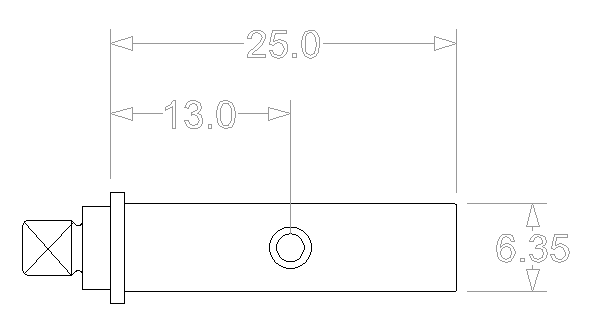

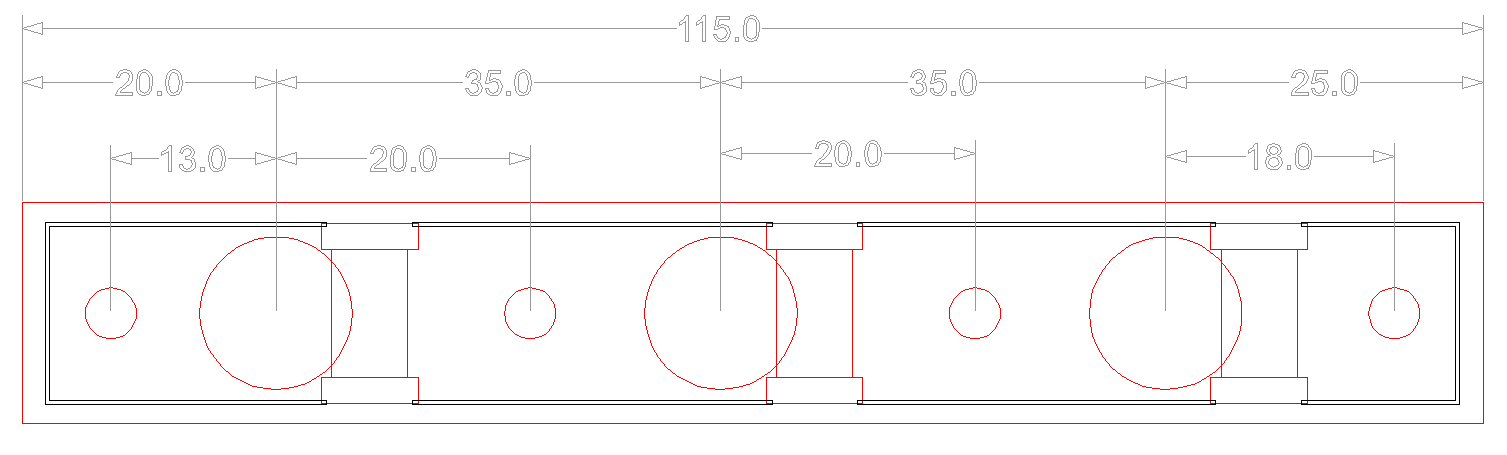

Headstock Drilling: Rodgers Tuners are precision machined to an accurate 35mm string roller spacing and 10mm diameter string rollers. If your headstock has 13/32″ string roller holes, please select 10.3mm diameter bearing bushes for your rollers when ordering.

Fitting Lacote tuners can be found on the lacote page.

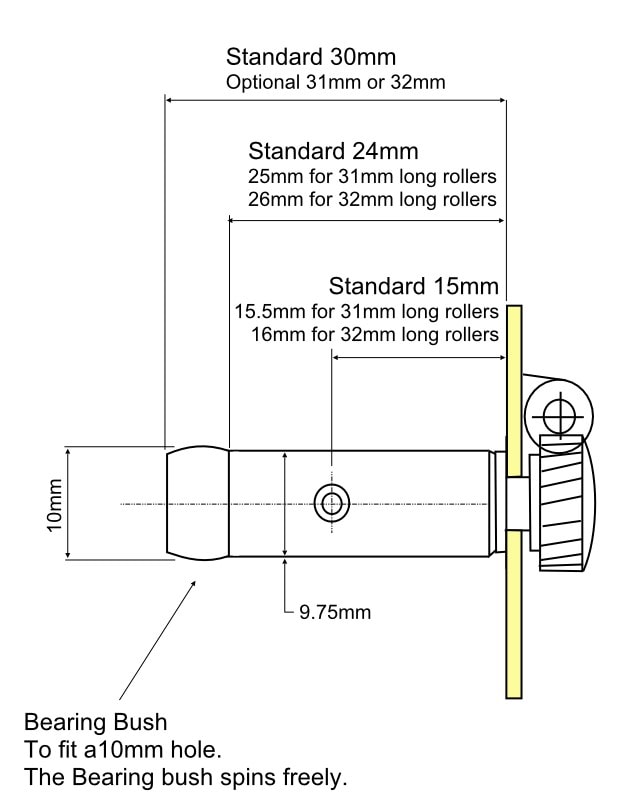

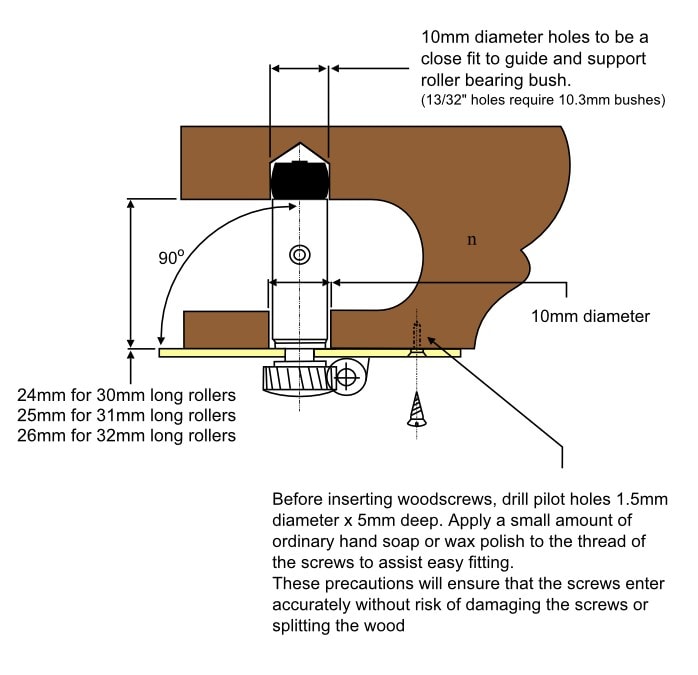

Tuners with Bearing Bushes for Slotted Head Instruments

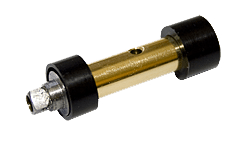

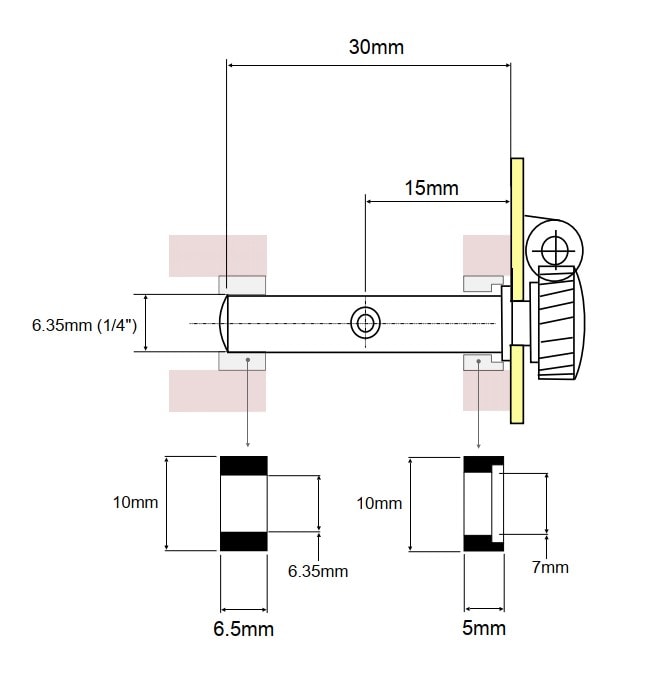

The Bearing bush is located to the string roller and spins freely. The shank of the roller is smaller in diameter eliminating the need for a clearance hole behind the side-plate.

Please note the maximum 24mm distance to ensure full location of the bush and hide it from view. If longer string rollers are required, we have 31mm and 32mm versions which can be selected when ordering.

If you are using an imperial drilling jig which drills the roller holes at 13/32″, we can supply 10.3mm bearing bushes. The ‘Y’ drill size is 10.26mm so unless it is cutting large, then 10.2mm bushes can be used.

It is however highly recommended to use a 35mm by 10mm drilling jig.

Locate the set on the headstock and mark the woodscrew holes accurately. Then pilot drill the holes 1.5mm diameter by 5mm deep. It is important that this is done accurately as poor fitting will affect the precision of the gearing and performance of the tuner.

Download the pdf

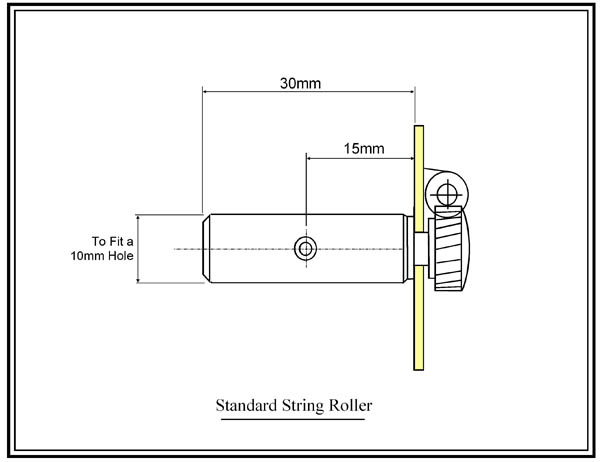

Fitting Plain Rollers for a Slotted Head Instrument

Plain classical rollers rotate plastic to wood inside the headstock. It is recommended to add a dry lubricant inside the inner hole where the roller located to prevent squeaking and allow for a smoother action. Bar hand soap or better yet, candle wax works well for this purpose. Please consider using rollers with bearing bushes instead. More information here.

A clearance hole in the headstock should be used behind the side-plate. This is to keep the roller properly rotating with its bearing diameter in the side-plate. This is important because the accuracy and performance of the gears is set by the exact position of the string roller. It also prevents squeaking of the roller on the wood.

Locate the set on the headstock and mark the woodscrew holes accurately. Then pilot drill the holes 1.5mm diameter by 5mm deep. It is important that this is done accurately as poor fitting will affect the precision of the gearing and performance of the tuner.

Download the pdf

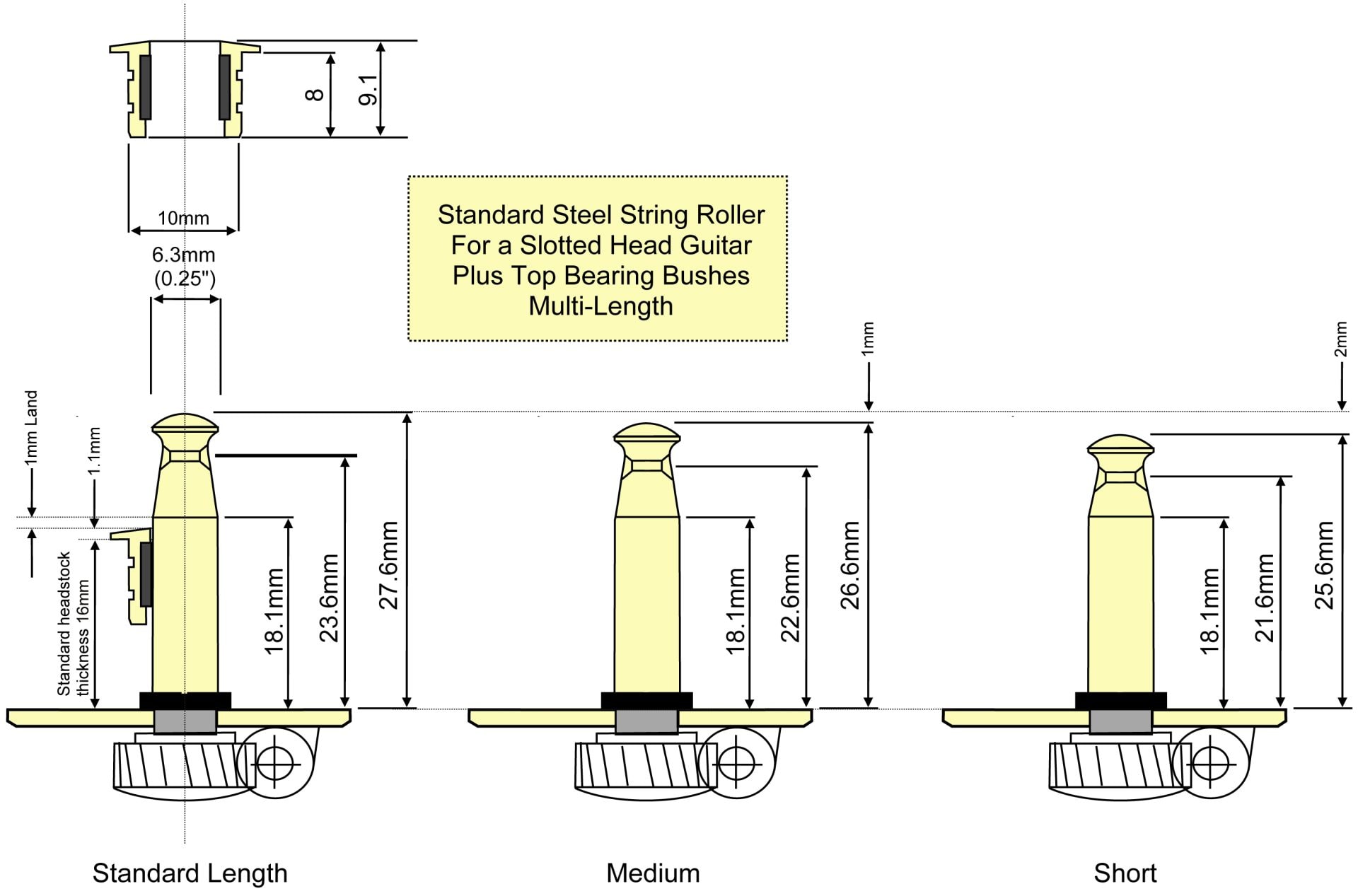

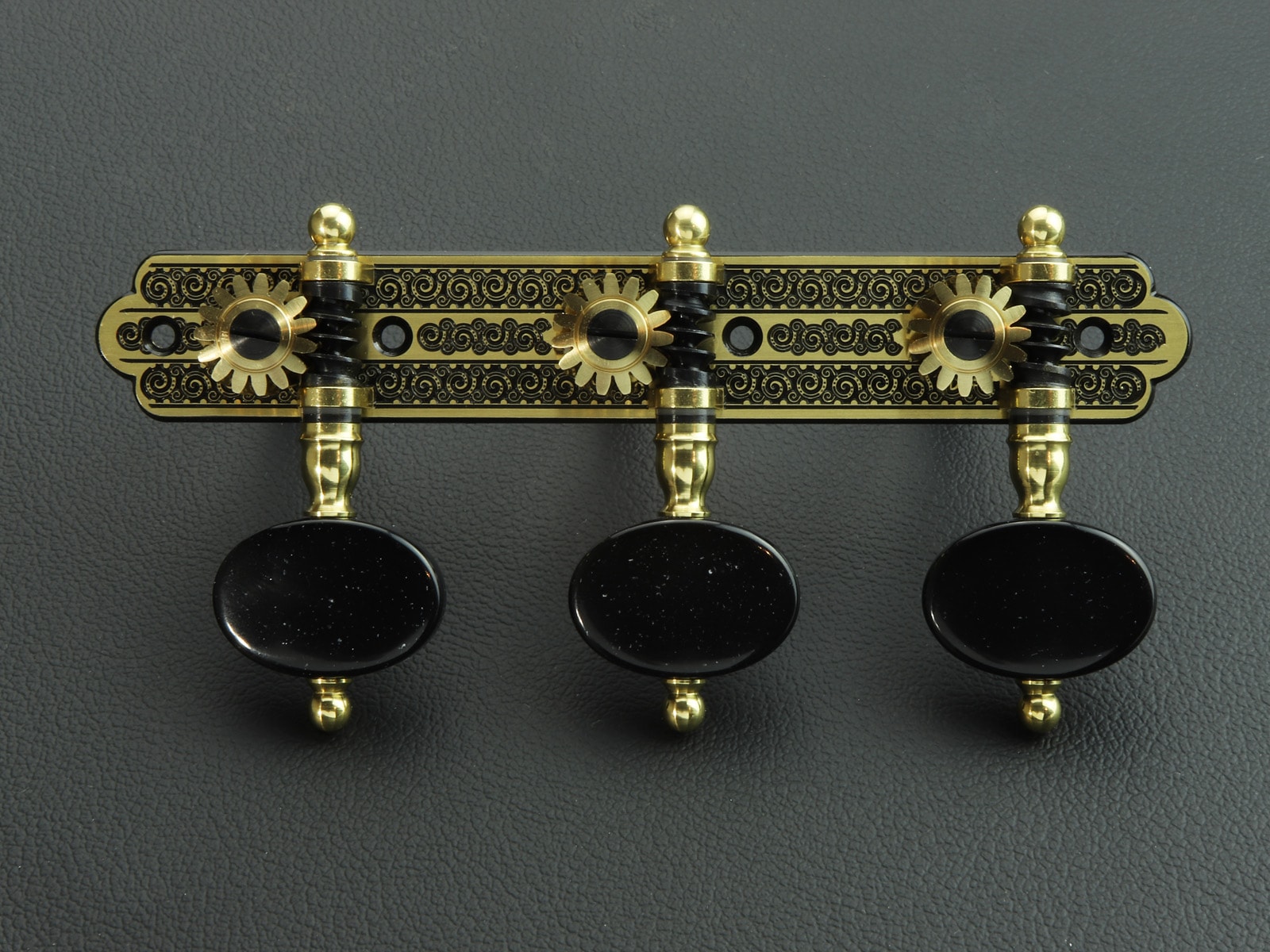

Fitting Steel String Slotted Head Tuners

The extra delrin bearing bushes are optionally used. The outer bush is a clearance bush that sits behind the side-plate. The inner bush supports the roller and prevents wear of the headstock which is greater than classical guitars because of the heavier string load and the smaller diameter of the string roller.

These bushes are not attached to the string rollers and must be bonded to the headstock. Once bonded, locate the set on the headstock and mark the woodscrew holes accurately. Then pilot drill the holes 1.5mm diameter by 5mm deep. It is important that this is done accurately as poor fitting will affect the precision of the gearing and performance of the tuner.

Download the pdf

Fitting Steel String Solid Head Tuners

The top bush has an outer diameter of 12mm and a shank diameter of 10mm. Meaning a flange of 1mm.

On the request of luthiers, these bushes are supplied as standard with 2 cylindrical grooves on the smooth fitting shank diameter (see image below). These are to be bonded into the headstock (usually with a cyanoacrylate adhesive), the grooves offering extra bonding location. Splined bushes are also available but be aware that the splined bushes can cause the surface lacquer of the headstock to crack or craze. This is why the smooth diameter bushes are our standard option.

The top bushes should be bonded to the headstock. They have an inner delrin bush which is a close fit to the roller and makes for a smooth and wear-free action. Once bonded, locate the set on the headstock and mark the woodscrew holes accurately. Then pilot drill the holes 1.5mm diameter by 5mm deep. It is important that this is done accurately as poor fitting will affect the precision of the gearing and performance of the tuner.

Download the pdf